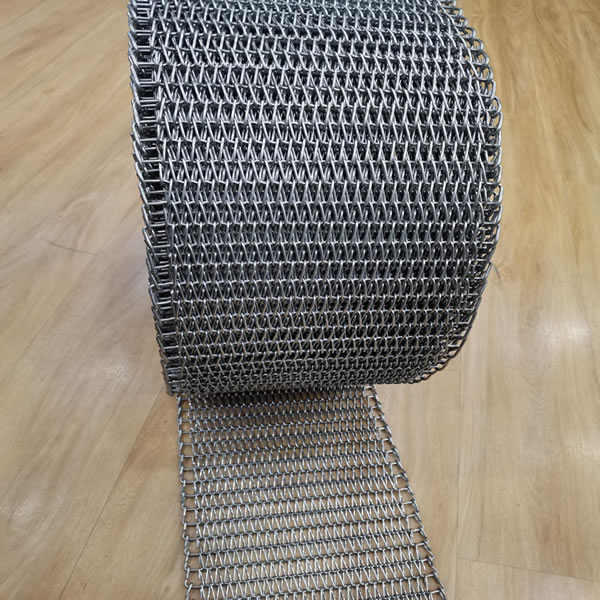

Balanced Weave Conveyor Belt

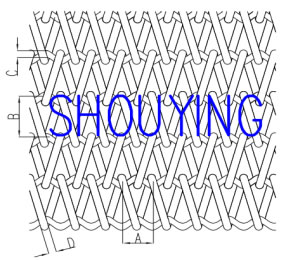

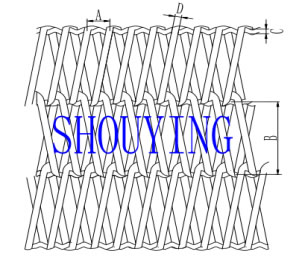

Balanced weave conveyor belt is constructed from alternating left and right hand spiral coils, which are woven together and joined by interconnecting cross rods.

This belt install easily with simple maintenance. Damaged sections of the belt are easily replaced by the end user, which allows for less downtime.

This belt is available in two basic types: standard balanced weave and double balanced weave.

The balanced weave conveyor belt is used more widely on more applications than any other woven wire mesh conveyor belt. Glass is annealed on it, potatoes drain on it, product cools on it, vegetables are washed on it, pretzels are salted on it. The uses of a balance weave conveyor belt in a conveying application are endless.

Specification

Wire type

|

|

| Flat Wire Type | Standard Type |

Edge types

|

Welded edge-mesh only |

|

Laddered edge-mesh only |

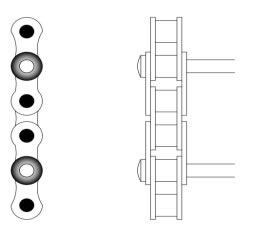

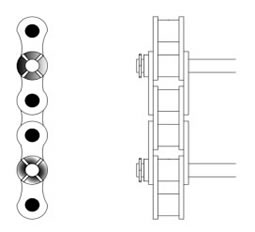

Chain edge driven mesh

The meshes can be driven by side chains using cross rods which are located through the mesh loops and then through chains at the end of the mesh. The types of cross rod finish at the exterior of the side chain are as follows:

With welded washer

|

It is the most common and economical style of finish to a chain edge belt, the cross rods through both mesh and edge chains. The cross rods are finished at the outside chains edges using a welded washer. |

With cotter pin & washer

|

It is less economical, but this type assembly allows clients to replace the edge drive chains when the mesh and rods are still workable. The cross rods are finished at the outside with a drilled hole to allow the fitment of a washer and cotter pin. |

In general the chain edge driven belts as shown above are available with 2 styles of edge chain.

| Single pitch roller chain | Double pitch roller chain |

|

|

Belt specification details

|

|

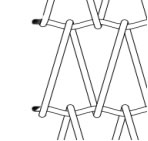

| Standard balanced weave conveyor belt | Double balanced weave conveyor belt |

| A | Spiral wire pitch |

| B | Crimp wire pitch |

| C | Crimp wire diameter |

| D | Spiral wire diameter |

General size

BW XX-YY-ZZ

BW: indicates a balanced weave mesh

XX: number of loops in 12 inches of belt width

YY: number of crimp wire in 12 inches of belt length

ZZ: wire gages used to produce belt

If two different sizes of wire are used, the gage of the crimp wire appears first followed by the gage of the spiral wire.

| Mesh type | Spiral wire pitch (mm) | Crimp wire pitch (mm) | Crimp wire diameter (mm) | Spiral wire diameter (mm) |

| BW12-10-8 | 25.4 | 30.5 | 4.11 | 4.11 |

| BW18-12-12 | 16.9 | 25.4 | 2.68 | 2.68 |

| BW18-17-10 | 16.9 | 17.9 | 3.43 | 3.43 |

| BW24-16-12 | 12.7 | 19 | 2.68 | 2.68 |

| BW24-21-1417 | 12.7 | 14.5 | 2.03 | 1.37 |

| BW24-22-12 | 12.7 | 13.9 | 2.68 | 2.68 |

| BW24-24-1214 | 12.7 | 12.7 | 2.68 | 2.03 |

| BW24-25-1012 | 12.7 | 12.2 | 3.43 | 2.68 |

| BW30-24-16 | 10.2 | 12.7 | 1.59 | 1.59 |

| BW30-28-18 | 10.2 | 10.9 | 1.21 | 1.21 |

| BW30-30-14 | 10.2 | 10.2 | 2.03 | 2.03 |

| BW30-30-18 | 10.2 | 10.2 | 1.21 | 1.21 |

| BW36-15-1214 | 8.5 | 20.3 | 2.68 | 2.03 |

| BW36-20-1012 | 8.5 | 15.2 | 3.43 | 2.68 |

| BW36-24-1214 | 8.5 | 12.7 | 2.68 | 2.03 |

| BW36-24-14 | 8.5 | 12.7 | 2.03 | 2.03 |

| BW36-24-1618 | 8.5 | 12.7 | 1.59 | 1.21 |

| BW36-28-10 | 8.5 | 10.9 | 3.43 | 3.43 |

| BW36-30-1214 | 8.5 | 10.2 | 2.68 | 2.03 |

| BW36-30-18 | 8.5 | 10.2 | 1.21 | 1.21 |

| BW36-32-1416 | 8.5 | 9.5 | 2.03 | 1.59 |

| BW36-36-18 | 8.5 | 8.5 | 1.21 | 1.21 |

| BW42-18-1012 | 7.3 | 16.9 | 3.43 | 2.68 |

| BW42-30-1012 | 7.3 | 10.2 | 3.43 | 2.68 |

| BW42-36-17 | 7.3 | 8.5 | 1.37 | 1.37 |

| BW42-38-16 | 7.3 | 8.0 | 1.59 | 1.59 |

| BW42-41-14 | 7.3 | 7.4 | 2.03 | 2.03 |

| BW48-26-1214 | 6.4 | 11.7 | 2.68 | 2.03 |

| BW48-36-16 | 6.4 | 8.5 | 1.59 | 1.59 |

| BW48-48-16 | 6.4 | 6.4 | 1.59 | 1.59 |

| BW48-49-18 | 6.4 | 6.2 | 1.21 | 1.21 |

| BW48-55-16 | 6.4 | 5.5 | 1.59 | 1.59 |

| BW60-24-14 | 5.1 | 12.7 | 2.03 | 2.03 |

| BW60-35-16 | 5.1 | 8.7 | 1.59 | 1.59 |

| BW60-36-16 | 5.1 | 8.5 | 1.59 | 1.59 |

| BW60-38-1416 | 5.1 | 8 | 2.03 | 1.59 |

| BW60-48-1820 | 5.1 | 6.4 | 1.21 | 0.88 |

| BW60-55-16 | 5.1 | 5.5 | 1.59 | 1.59 |

| BW72-24-16 | 4.2 | 12.7 | 1.59 | 1.59 |

| BW72-36-16 | 4.2 | 8.5 | 1.59 | 1.59 |

| BW72-48-16 | 4.2 | 6.4 | 1.59 | 1.59 |

| BW72-66-18 | 4.2 | 4.6 | 1.21 | 1.21 |

| BW72-72-20 | 4.2 | 4.2 | 0.88 | 0.88 |

| BW84-84-17 | 3.6 | 3.6 | 1.37 | 1.37 |

We can produce any type of balanced weave conveyor belt, if you have any inquiry, please contact me.

Materials available

Stainless steel 304

Stainless steel 316

Stainless steel 316L

Manganese steel

Galvanized steel

Other materials demanded by the clients.