Chain Driven Conveyor Belt

Chain drive conveyor belt is a kind of conveyor belt. It is mainly used to convey different objects. It is driven with a cross rod which connects the chain strands by either passing through or under the wire mesh fabric, the density of wire mesh fabric is chosen according to size of the product conveyed on the belt.

Chain driven conveyor belt assemblies employing a chain edge are also widely used due to their uniformity in pitch, high tensile strength with relatively light belt/chain weight, and good durability under severe loads.

Many different wire mesh configurations are available, including balance weave, double balance weave and conventional weave. Plastic modules are also available to serve as the product support surface.

It is usually used in conveyor roasting machine, baken oven, quenching tank, washing machine, fryer and freezer.

Specification

Belt edges

The types of cross rod finish at the exterior of the side chain are as follows:

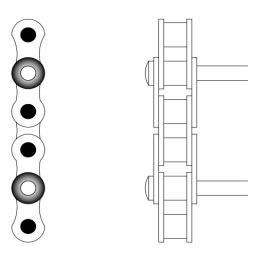

With welded washer

|

It is the most common and economical style of finish to a chain edge belt, the cross rods through both mesh and edge chains. The cross rods are finished at the outside chains edges using a welded washer. |

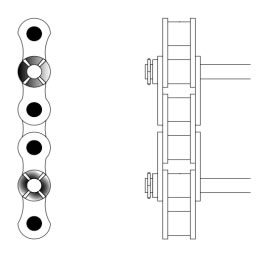

With cotter pin & washer

|

It is less economical, but this type assembly allows clients to replace the edge drive chains when the mesh and rods are still workable. The cross rods are finished at the outside with a drilled hole to allow the fitment of a washer and cotter pin. |

Roller Chain Selection

Chain is normally selected according to the strength and speed required. The most frequently used types of chain for metal mesh conveyors are roller chain, employed for most room-to-medium temperature applications, and for heavier loads and higher temperature.

Typical chains for mesh belts

|

|

| Single pitch roller chain | Double pitch roller chain |

Roller chain parameters

| Single pitch roller chain | |||||

| Chain No. | Pitch | Rod diameter | |||

| ISO GB | ANSI | mm | inch | mm | inch |

| RC40 | 08A | 12.7 | 1/2” | 3.94 | 0.156” |

| RC50 | 10A | 15.875 | 5/8” | 5.08 | 0.200” |

| RC60 | 12A | 19.05 | 3/4” | 5.94 | 0.234” |

| RC80 | 16A | 25.4 | 1” | 7.94 | 0.312” |

| RC100 | 20A | 31.75 | 1 1/4” | 9.5 | 0.375” |

| RC120 | 24A | 38.1 | 1 1/2” | 11.1 | 0.437” |

| Double pitch roller chain | |||||||

| Chain No. | Pitch | Roller diameter | Rod diameter | ||||

| ISO GB | ANSI | mm | inch | mm | inch | mm | inch |

| C208B | 2040 | 25.4 | 1” | 8.5 | 0.335” | 4.45 | 0.175” |

| C208BL | 2042 | 25.4 | 1” | 15.88 | 0.625” | 4.45 | 0.175” |

| C210A | 2050 | 31.75 | 1.25” | 10.16 | 0.40” | 5.08 | 0.200” |

| C210AL | 2052 | 31.75 | 1.25” | 19.05 | 0.75” | 5.08 | 0.200” |

| C212A | 2060 | 38.1 | 1.5” | 11.91 | 0.469” | 5.94 | 0.234” |

| C212AL | 2062 | 38.1 | 1.5” | 22.23 | 0.875” | 5.94 | 0.234” |

| C216A | 2080 | 50.8 | 2” | 15.88 | 1” | 7.94 | 0.312” |

| C216AL | 2082 | 50.8 | 2” | 28.58 | 1.125” | 7.94 | 0.312” |

| C220A | 2100 | 63.5 | 2.5” | 19.05 | 0.75” | 9.5 | 0.375” |

| C220AL | 2102 | 63.5 | 2.5” | 39.66 | 1.561” | 9.5 | 0.375” |

The above roller chain size are the general size, if you need other types roller chain, please contact me.

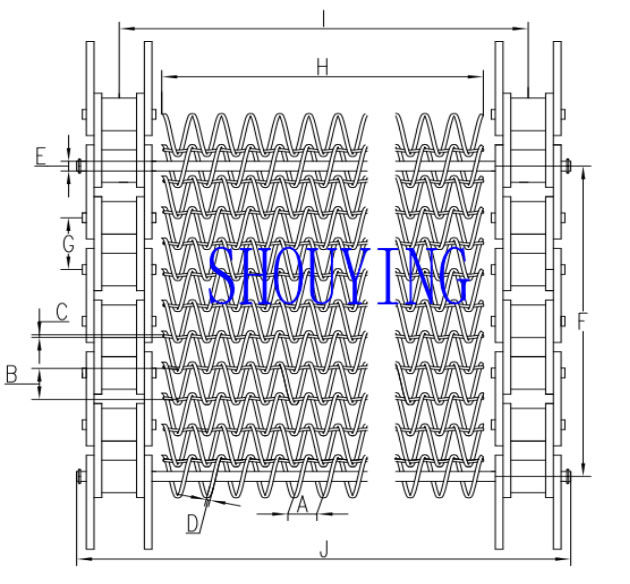

Belt specification details

| A | Spiral wire pitch | F | Rod pitch |

| B | Crimp wire pitch | G | Roller pitch |

| C | Crimp wire diameter | H | Mesh width |

| D | Spiral wire diameter | I | Roller centre width |

| E | Rod diameter | J | Overall width |

Materials available

Stainless steel 304

Stainless steel 316

Stainless steel 316L

Other materials demanded by the clients.